The Magnificent Swallowtail Kite

made in USA

Home Page

Profile

How to Order

Blue

Lightning

Custom Stencil

KnifeMaker

Fingerprint 1

KnifeMaker Fingerprint 2

KnifeMaker Fingerprint 3

Blue

Lightning Etch

Customer's

Personal Stencil Addition

Blue Lightning

Tips

Etch your logo into Damascus

Etching Power Supply

Blue Lightning Stencil: Price List

Bowies page 1

Bowies page 2

Lockback

Folders

Links

Tutorials

Stabilized Leather

Moose Antler

Stabilized

How to etch your Logo into your knife

HARD Felt Knife Honing

Wheel

Leather Stamp Custom Logo

Knife Maker

Label the WORLD

Contact via email:

shrpknife@aol.com

HARD FELT STROP/HONING WHEEL

Home Made / Hand Made

Blue Lightning Hard Felt Strop/Honing Wheel

All

Parts/ingredients and the Knifemaker were made in

the

USA

HOME / SECRET RECIPE

Felt used was made by

Eco-fi is the high-quality PET fiber

made from 100% post-consumer recycled plastic

bottles.

Felt used to make wheels was purchased from

Joann Fabrics and Crafts, Waterford, Orlando ,

Florida

Felt stabilized using a similar process following

the Loctite System

My home stabilizing system follows the LOCTITE

system using simpler parts/units .

The stabilizing is used for wood, antlers,

cloth,

felt, any material that will absorb water.... plus metal units

Here is the information Link

Link for Stabilizing Help Instructions

Open using Adobe Acrobat

Knife in

the first picture below is Homemade using ATS-34 kitchen knife razor sharp

displayed in a piece of sliced paper. Rouge used is dry White rouge.

Wheel diameter is 7.000, Width 1.500", Bore .750".

This was the first one.

Fabric displayed is

"Rainbow Classic Felt"

100% Polyester ....Made from recycled post-consumer plastic bottles.

Might be one of your used bottles....

Final step for Sharpening the WORLD'S

Knives !

WORKS GREAT !!

Second wheel, on left, was made with same material

is 1.250" thick by 9.00"Diameter

with a one inch bore.

This bore size allows easy addition of different size bushings

Again...

WORKS GREAT !!

BLUE LIGHTNING !!

Hard Felt Strop/Honing Wheel.

All parts and ingredients plus the Knifemaker were made in the

USA

Hard felt honing wheel on the left is used for the final step in

sharpening

your knives.

This Honing Wheel is used with or without white rouge buffing compound.

The wheel (Blue) is for needed sharpening before honing wheel on left.

It is used with a 3/4 HP Baldor Buffer....1800 RPM

The buffer can easily be rotated 180 degrees or any angle you want..

It will give you a sharpened knife that is a step above razor sharp !

The above left Honing Wheel is same materials different color

The Blue Lightning Honing Wheel

is on the right.

BLUE LIGHTNING !

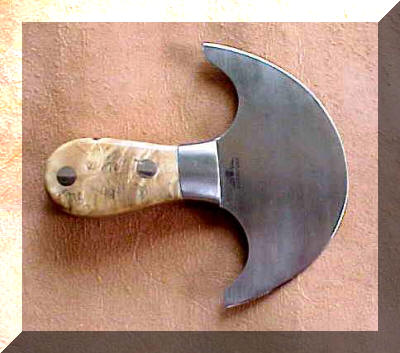

Top picture on left is a Round / Head knife

for cutting leather.

Handle California Buckeye Burl...stabilized

Blade is ATS-34, Rc 60-61, 1/16 inches thick 4.5 inches wide.

Top right picture is the same type round knife...Handmade.

It was sharpened as a test. It was not sharpened and then honed with

the Felt Wheel.

It was completely sharpened with the Felt Wheel. ... razor sharp

10 minutes to sharpen. Had it already been sharpened and was just dull

it would be razor sharp in 5 minutes.

Picture on left below the Round knife ...Brand new Strop/Honing wheel.

Picture on right is dual system.

The wheel on the left is 1.125" width and diameter is 10.250"

It has 600 grit Silicon Carbide added for final honing

of cutting edge.

Picture on bottom left is an Estwing Hatchet

that can be sharpened,5160 steel.

Round/Head Leather Knife can also be sharpened... no problem.

Quick note: No rouge is used or needed.

The wheel on right is 1.375" wide by 10.259" diameter.

It is for stropping with white rouge...no

Silicon Carbide

This left picture is the Handmade "Blue Lightning" wheel. It is

10 1/4" in diameter and is 1 1/4" thick with a 3/4"arbor

hole.

Ingredients: Basic wheel as above with added 600 grit Silicon Carbide..

In the picture is the Silicon Carbide used added into the recipe.

Following is Quote for uses from Brownells

"Very fine abrasive powders you can use to “rub in” parts.

Make an abrasive/cutting-oil paste for metal work or use dry

on a soft pad to bring a cured stock finish to a gloss. "

You can buy a compound that has Silicon Carbide in it that you add to the

wheel

For this wheel it is constantly there working for you.

The test knife is an ATS-34 stainless steel knife ( HandMade )

mirror

polished ready for sharpening.

Usually done after the handle and bolster are put on.

The knife blade edge was .015 " thick and not sharpened.

All of the sharpening was done with the new Silicon Carbide wheel.

The first major sharpening test...WORKED... to razor sharp

without using a grinding wheel or belt.

Honed completely

sharp...ouch...completely :)

Wheel will handle CPM-S35VN ....no problem

Step 1: If needed clean wheels by using a piece of used 2" X 72" 36 grit grinding belt.

Just rip belt apart by hand into about a 6" to 8" section.

Place it in front of a hard block of wood. Then hold the block against

the wheel.

It will remove all white rouge you have used....or anything else that is on

the wheel.

Step 2: Sharpen major dull knife with the clean Silicon Carbide

Blue Wheel...no White Rouge.

Step 3 : Add White Rouge to the white wheel to mirror polish cutting

edge ( if you want to ).

Then cut

a piece of leather to totally remove the feather edge.

BS KNIFE

( NO Bull Shit )

You can sharpen a worn out Band Saw Blade. Just start the Band

Saw and

use a hand drill with reversible rotation. Install a grinding bit

and hold it against the Band Saw blade at a good angle to remove

the kerf generated by a new Band Saw blade. Leave

some of the gullets in bottom of the Band Saw teeth.

Here is the result of the sharpening to cut

Chrome Tanned Water Buffalo Leather ..... 5-6 oz. Chocolate

The left picture shows straps that have a wave border for different design

rather than straight cut. They were cut with the razor

sharp Bandsaw blade on the JET metal cutting band saw on the right.

The bottom picture is the sharpened Bandsaw blade. The edge top will be

flattened and you will

have a serrated cutting knife edge.

If you want a circular rotating knife blade just apply the sane grinding

steps to a plywood saw blade.

BS KNIFE is

a dull Band Saw Blade

PROUDLY SERVING THE WORLD

ALABAMA, ALASKA, ARIZONA, ARKANSAS,

AUSTRIA, AUSTRALIA, BELGIUM, Brazil, BULGARIA,

CALIFORNIA, CANADA, CZECH

REPUBLIC, COLORADO, CONNECTICUT, Costa Rico, CROATIA.

DELAWARE, ENGLAND, FLORIDA, FRANCE, GEORGIA,

GREECE,

HAWAII, ICELAND, IDAHO, ILLINOIS, INDIANA, IOWA,

IRELAND, ISRAEL, JAPAN, KANSAS, KENTUCKY,

LOUISIANNA MAINE,

MARYLAND, MASSACHUSETTS, MICHIGAN, MINNESOTA,

MISSISSIPPI, MISSOURI, MONTANA,

NEBRASKA,

NETHERLANDS, NEVADA, NEW HAMPSHIRE, NEW JERSEY, NEW MEXICO,

NEW SOUTH WALES,

NEW

YORK, NEW ZEALAND, NORTH CAROLINA, NOVA SCOTIA,

OHIO, OKLAHOMA,

OREGON, PENNSYLVANIA, RHODE ISLAND, PORTUGAL,

SCOTLAND,

SINGAPORE, SOUTH CAROLINA, SOUTH DAKOTA, SWEDEN, SWITZERLAND, THAILAND,

TASMANIA, TENNESSEE, TEXAS, UNITED

KINGDOM, UTAH, VIRGINIA, WALES,

WASHINGTON, WEST VIRGINIA, WISCONSIN, and

WYOMING.